Table of Contents

- Understanding Steel Frame Screws

- Why Screw Selection Matters

- Types of Steel Frame Screws

- Application of Steel Frame Screws

Understanding Steel Frame Screws

Steel framing has revolutionized modern construction, offering unmatched strength and durability. However, the success of your steel frame project hinges on one crucial detail: choosing the right screws. Steel frame screws, as known metal stud screws or metal framing screws. This comprehensive guide will help you make informed decisions for your construction needs.

Why Screw Selection Matters

Selecting the appropriate steel frame screws isn't just about holding things together – it's about ensuring structural integrity, safety, and longevity. Here's what's at stake:

- Structural Integrity: Proper screws maintain load-bearing capacity.

- Installation Efficiency: The right screws can reduce installation time and labor cost.

- Cost-Effectiveness: Correct selection prevents costly repairs and replacements.

Types of Steel Frame Screws

Steel framing requires specialized screws, and the type you choose depends on several factors, including the steel gauge, the application, and the material you’re fastening.

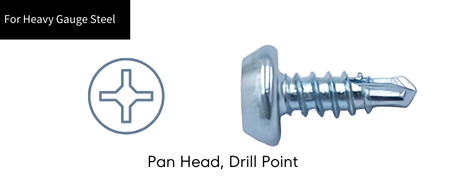

1. Self-Drilling Screws for Heavy-Gauge Steel

When working with heavy-gauge steel, such as thicker structural steel, self-drilling screws are the most efficient solution. These screws are designed with a drill-bit tip that allows them to drill their own pilot hole as they are driven into the steel. This feature required no pre-drilled holes, speeding up the installation process. Self-drilling screws are ideal for heavy-gauge steel because they can penetrate thicker material quickly without the need for additional drilling.

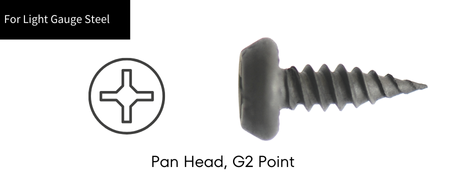

2. Sharp-Point Framing Screws for Light-Gauge steel

These screws ensure quick penetration into thinner materials without causing damage. The sharp point, often enhanced with patent-protected technology, G2 Point offers a more efficient starting point and drives stability than traditional screws. In fact, G2 Point allow for a 60% faster installation when compared to standard screws, providing a significant efficiency boost during construction.

Applications of Steel Framing Screws

Screws for steel framing are used in various applications throughout the construction process. Each type of screw serves a specific purpose, ensuring that materials are securely fastened, whether it's for basic framing or attaching exterior materials. Below are some common applications:

- Framing and Track: These screws are used to join structural steel members such as tracks and studs, which form the skeleton of a building.

- Clips: Clips are used for connecting smaller steel sections to the main framing, securing items like junctions and corners.

- Joists: Screws used for attaching joists to steel framing to support flooring and ceilings.

- Prefab Panels: Fastening pre-constructed steel panels to the framework, helping to form walls and roofs.

- Flat Strapping: Used to provide additional support and stabilization to the steel structure, often in areas that require extra strength.

These applications illustrate the versatility and necessity of using the correct screws for each type of steel frame connection.

Ready to select the best screws for your steel framing project? Contact us and let's explore our range of high-quality screws designed for heavy-gauge and light-gauge steel, or contact our expert team for tailored advice. Whether you need assistance with material selection or fastener recommendations, we’re here to help ensure your construction project runs smoothly and efficiently.