Chipboard screws, also known as particleboard screws are a variation of self-tapping screws specifically designed for use with engineered wood like chipboard, particleboard. They have full or partial coarse threads that allow efficiency in the installation process and provide strong holding power in materials. Typically avoid splitting or breaking than solid wood. Most often, chipboard screws have a zinc-plated or yellow look in applications. The common head style is flat head chipboard screw that allows a smooth finish without burrs. Moreover, chipboard screws can be made of varying materials like stainless steel and other types of steel which undergo treatments to enhance their durability and corrosion resistance.

1. What are the key features of chipboard screws?

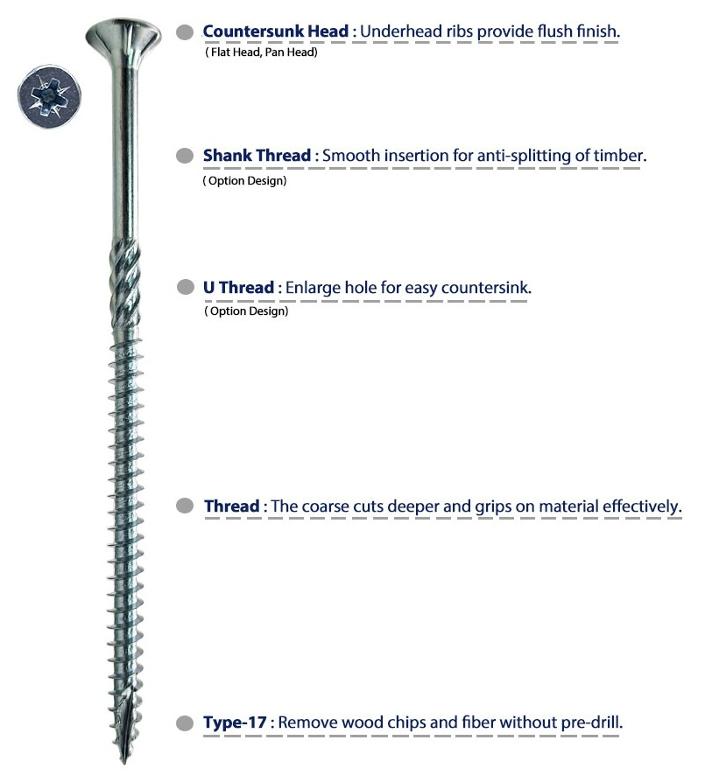

Here are the main components. The picture shows the partial thread chipboard screw, full thread is available.

- Head: Chipboard screws typically feature a countersunk head, which allows the screw to be flush and clean on the surface of the material. Additionally, the flat head chipboard screw with ribs is popular option due to perfect self-countersinking and easy insertion. Patented MS head is perfect countersunk to suit for versatile material.

- Shank: This is the smooth part of the screw below the head. It's designed to slide through of upper piece without gripping, allowing for anti-splitting and saving materials.

- U Thread: This design help to enlarge hole the, providing better drilling and countersink.

- Thread: Chipboard screws have coarse threads that are specifically gripping effectively. The coarse thread cuts deeper into materials like particleboard and medium density board. Patent Twister is unique and tailor design for woodworking.

- Sharp Point: The tip of a chipboard screw come with extremely sharp and self-tapping, allowing it to start easily without pre-drilling.

- Type 17: Type 17 screws help to remove wood chips and fibers when drilling, reducing overall torsion on the screw heads and driver.

2. What are the applications of chipboard screws?

Chipboard screws are versatile fasteners with a wide range of applications in woodworking and construction. Here are some common uses:

- Furniture assembly, especially for pieces made from particle board.

- Cabinet making and installation.

- Attaching hinges and hardware to engineered wood products.

- General construction with plywood, OSB, or other engineered wood panels.

- DIY projects using particle board.

Whether you're a professional carpenter or a DIY enthusiast asking "How do I choose the right screws for my woodworking project?", chipboard screws are often a great choice for working with engineered wood products.

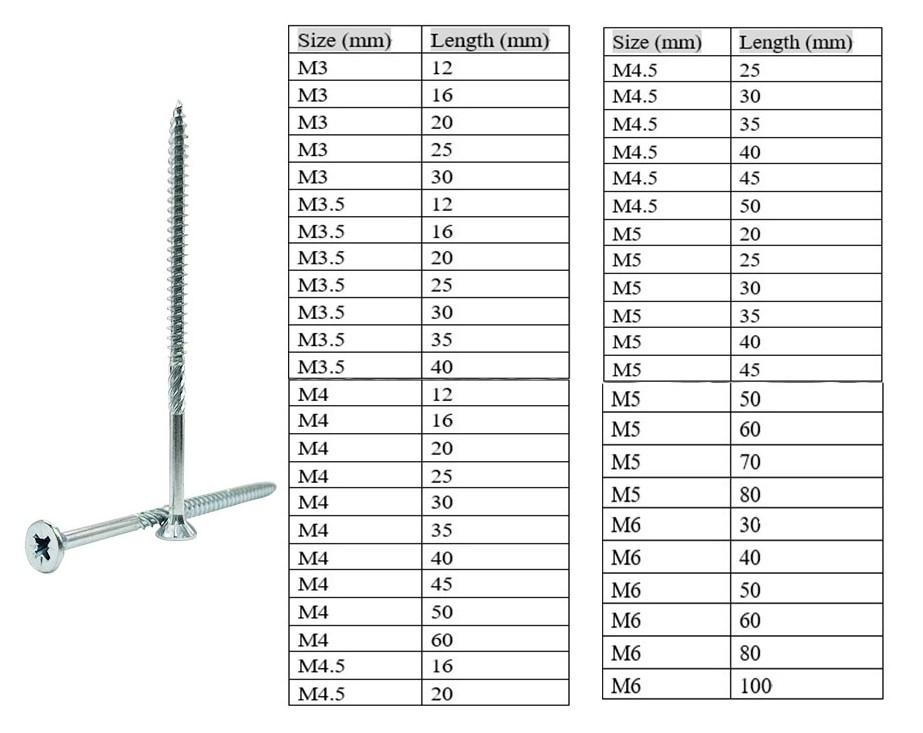

3. What sizes are available for chipboard screws?

Chipboard screws come in a variety of sizes to suit different applications. Regular size chart as reference, large size is available. (Head to M8 / Length to 300mm).

If you require further information, please contact us.